Obsessed with details.

What Peter Müller begins, he pursues excessively. He actually came to skywalk through FLYSURFER, because his first contact with the company came from Peter’s kite career. The tinkerer was initially under contract with FLYSURFER as a kite professional back then. To this day, Peter is one of the best kite surfers in Germany.

Addicted by the curiosity about flying, he could only be found in the air, mastering the paraglider. Today Peter is responsible for harness and accessory development at skywalk. He quickly builds many prototypes out of a flash of thought. But mostly his ideas quickly find acceptance and become much sought-after models – like the RANGE X-ALPS2, which was the first harness with our PERMAIR technology in our product range back in 2017.

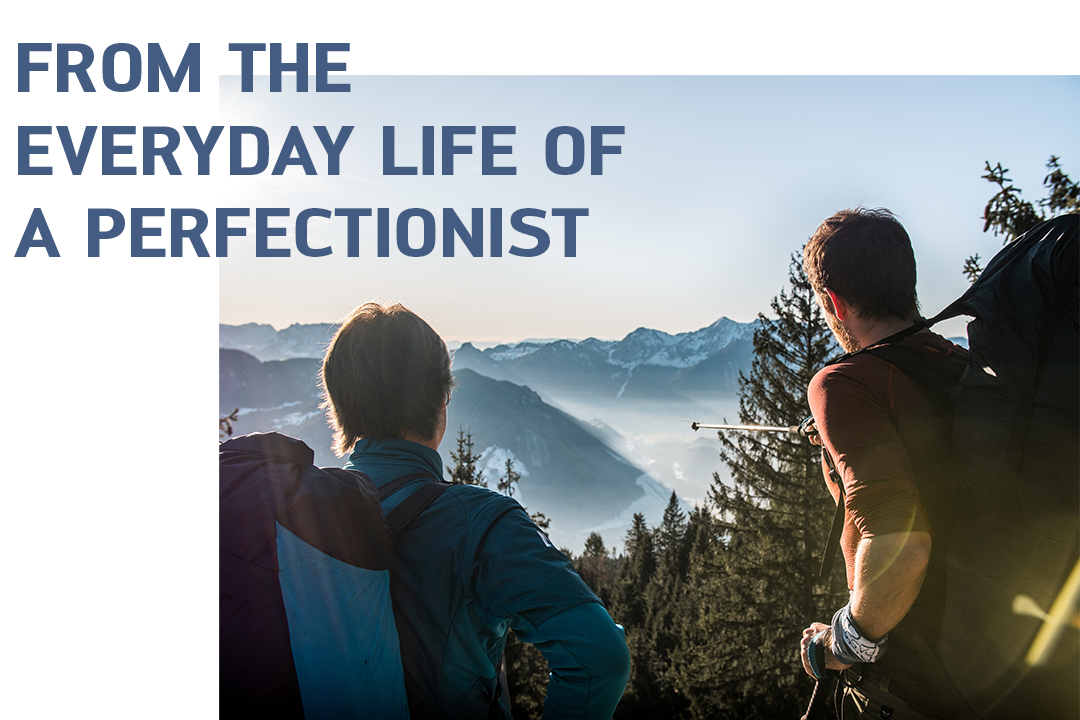

The Achental valley is one of these special places. Ten kilometers to the north, Lake Chiemsee offers a mediterranean flair. Ten kilometers to the south, the rugged peaks of the “Wilder Kaiser” rise into the sky. For Peter Müller, it has become the center of his life.

Peter Müller and Dominik Asteiner are responsible for the development of harnesses, rucksacks and paragliding accessories at skywalk. The two of them test their freshly sewn prototypes preferably on the Hochgern, which is located directly behind the skywalk headquarter.

They use the ascent to discuss about carrying comfort and suitability for everyday use of the next backpack generation: “For many people a Hike&Fly rucksack is just another backpack. But you can’t compare it to a trekking backpack“, says Peter.

At the launch site below the Hochgern summit, the focus is on Peter’s new harness. Together Peter and Dominik check the geometry with the hinging points of the shoulder and back straps and take a close look at the seam pattern. Peter knows that every seam must be done right so that everything works together.

Both argue how the volume can be better distributed so that the carrying system can be adapted to completely different body shapes. They are also looking for new materials that ideally weigh less than 300 grams and yet can withstand high peak loads, such as when the owner yanks his backpack by the corner out of a stuffed car trunk.

After landing, modifications are implemented directly on the sewing machine or on the computer. “We love the direct workflow, so we can make targeted and efficient alterations. The ideal location offers the best conditions for this, ”says Dominik.

Privilege of skywalk employees: Landing site close to the workplace. Hike&Fly excursions to the Hochgern are a daily occurrence.